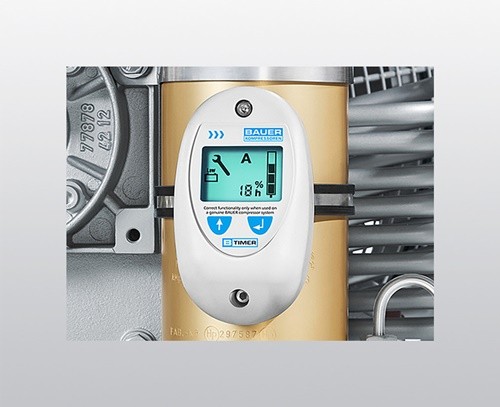

The interaction concept has been completely redesigned. The new user-friendly display and navigation standards are now virtually identical for the B-CONTROL MICRO and the B-CONTROL II.

In addition to the control and supervision of important plant functions, B-CONTROL II offers additional convenient features, such as. For example, the data logger, a USB connection, common interfaces such as Modbus, CAN bus or Profibus, or integrated control of an interconnected system with up to four compressors. Additional sensors and equipment can be connected, for example. For example, for monitoring intermediate temperatures and pressures, remote data transfer via B-MESSENGER, remote operation via external operating area, etc.

The B-CONTROL II can be adapted to individual requirements and expanded to complete system process control.

Features:

- 5.7 ″ TFT color touch screen with text display.

- Fully automatic monitoring of relevant parameters, compressor shutdown in case of values outside the permitted range.

- Language selection (German, English, French, Italian, Dutch, Polish, Spanish, Czech, Portuguese, Chinese, Japanese, Russian and more).

- Oil pressure monitoring, among other things, as protection against incorrect direction of rotation.

- Maintenance management: on-screen display of maintenance information.

- Event history.

- Password protection for different menu levels.

- Basic load change operation and combined operation for up to 4 compressors.

- Integrated data logger.

- Cycle counter for recording the end-separator loading cycle change.

- Interface: USB 2.0, Ethernet 10/100, CAN bus layer 2, Modbus RTU RS485, Profibus DP slave (optional).

- Remote connection / disconnection (potential free).

- Compilation fault message (potential free).

- Simple software update via CF card.

- External connection possibilities for: B-SECURUS, SECCANT, B-KOOL, B-DETECTION, external display, external operating area, gas level gas cylinder, gas measuring systems.

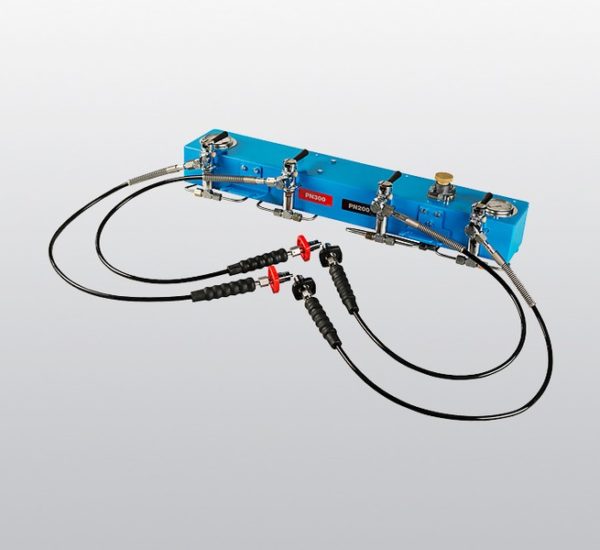

Control and automatic purging

Simple and intuitive operation of our portable compressors is realized by an integrated compressor control as standard. In the case of stationary installations, B-CONTROL controls and supervises all functions of the BAUER compressor installation.

An informative and user-friendly screen displays all information about the normal operating status of the installation. In case of detection of deviations, B-CONTROL automatically shuts down the compressor and shows the source of the error on the screen.

The advanced version of the B-CONTROL MICRO is the B-CONTROL II. This control offers additional convenient functions.

Fully automatic operation allows an automatic purge activated by an electronic control. The condensate generated can be collected in a collection vessel and disposed of in an environmentally compatible way.