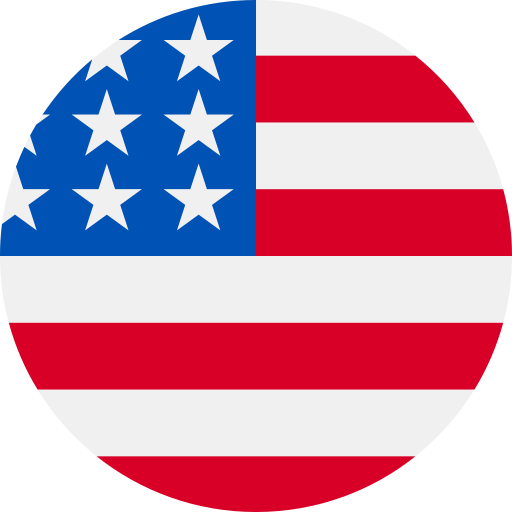

On the four-part display you can follow the increase in the degree of saturation of the P filter cartridge at any time. In case of a remaining capacity of less than 20%, the last segment starts flashing and, instead of the operating hours, the number of the filter cartridge is displayed for a possible ordering process. If the cartridge is full, all 4 display segments will flash.

The key symbol indicates the need for maintenance. The letters A to C indicate the required BAUER maintenance interval.

Safety: The battery indication warns you when the battery needs to be changed.

When replacing the battery or in case of prolonged storage without battery, the operating hours and maintenance times are saved in the device’s RAM memory.

Simple mounting: no tubes or wires, a screwdriver is enough!

Extremely robust: for universal use, even in the harshest outdoor conditions: protection against dust and water splashes, resistant to salt, intense sunlight, high humidity and sand.

Bauer products

Whether you are a diver or firefighter who relies on pure breathable air according to DIN EN 12021 or you want to rely on perfectly treated compressed air for sports applications, for example when filling paintball cartridges – decades of experience of BAUER air treatment, intensive basic research and the most demanding material tests strive for extraordinary quality and highest safety.

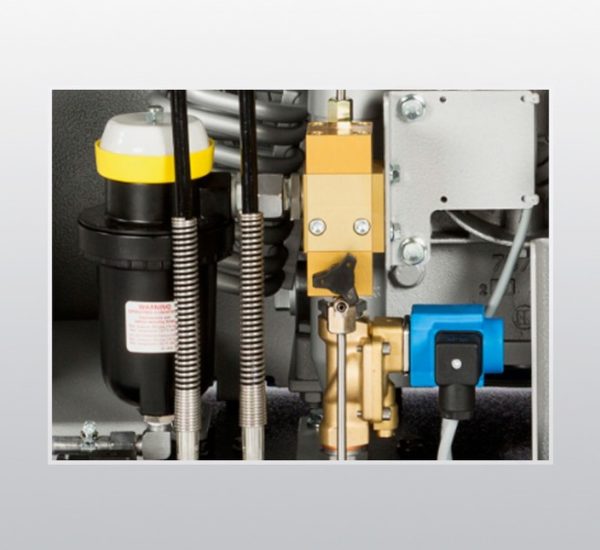

Our goal in treating high-pressure compressed air and gas is to reduce fouling caused by moisture, CO, CO2 , oil and particles.

The air quality generated by BAUER P filtration systems exceeds the requirements of the respiratory protection standard for compressed gases DIN EN 12021¹. Furthermore, the air quality generated with a BAUER filter system conforms to the following international standards: STANAG 1079 mW, Britisch Standard 4001, US CGA Spec. G.7.1, Canada CSA Standard Z 180.1, Australian Army Standard 5017¹.

The prerequisites for this are the use of suitable BAUER filter cartridges as well as the correct location and regular maintenance of the compressor.

Other BAUER treatment systems and monitoring equipment provide additional safety in specific areas of application.

In case of correct installation and maintenance of the systems according to the service manual and in case of use of the BAUER AERO-GUARD, provided that the CO2 concentration in the aspirated air exceeds the predetermined standard values.