WORKING CAPACITY

- Ø 2.4 mm to 6.4 mm for aluminum and copper

- Up to Ø 6 mm for steel

- Up to Ø 5 mm for stainless steel

- Maximum head diameter 11.4 mm

- Rivet body length greater than 30 mm

- Maximum setting force of 12,000 N with air pressure of 6 bar

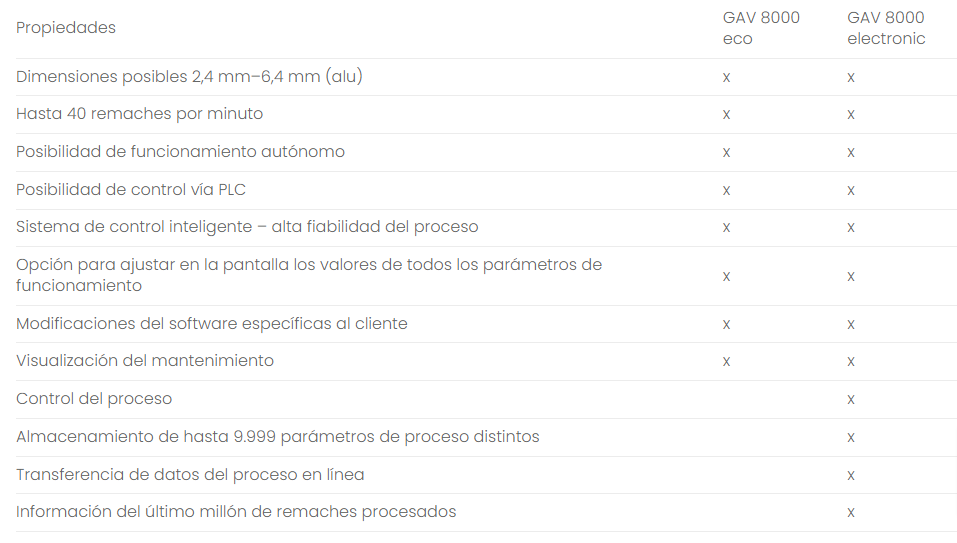

GAV 8000 ECO/ELECTRONIC COMPARISON

The GAV 8000 electronic riveter has a riveting process control system. The combination of the documented rivet function, together with the control of the GAV 8000 electronic application process, guarantees reliability as the joints are made. The GESIPA® integral quality management system ensures precision from the early stages of production to the moment the blind rivet is processed.

GAV AUTOMATIC RIVETING

All the riveters we manufacture at GESIPA® are perfectly suited for mass production in industrial centers. The individual configuration means that the GAVs can be controlled by an operator or installed as part of a robotic application. Even installation in a system does not cause any problems and there is the possibility of updating it. Our riveters can be adapted according to your specific needs and our product portfolio covers a wide range of processing tasks. Do not hesitate to contact us. We will be happy to help you with your projects!

PRACTICAL MODULAR PRINCIPLE

We have a wide range of accessories for GAV, which facilitates the option of creating different variants. By adapting the solutions according to your specific needs, it is possible to increase profitability. If you need to change the application, it is possible to adjust GAV accordingly quickly and easily.

INDUSTRIAL USE IN ROBOTIC APPLICATIONS

All GAV models can be integrated into robotic systems and industrial robots are used in almost all sectors of the manufacturing industry. They can be programmed for all kinds of movement sequences, which allows them to be used very effectively together with GESIPA® riveting technology. With controlled, fast, and reliable processes, the use of a fully automatic GAV combined with a linear system or a multi-axis robot offers several advantages:

- Maximum precision

- Excellent profitability

- Short cycle times

- High degree of flexibility

QUALITY MANAGEMENT SYSTEM

The GESIPA® quality management system ensures accuracy from the early stages of production to the moment the blind rivet is processed. The combination of the documented rivet function and the GAV 8000 electronic process control guarantees reliability as the joints are made. The quality management system is based on three points:

- Measurement evaluation

- Function evaluation

- Riveting process control

The measurement and function evaluations are carried out at the GESIPA® plant, while the riveting process control takes place at the customer’s facilities.