At the same time, a suitable storage module ensures a perfect distribution of compressor run time and also serves as a waterhammer buffer.

The storage systems are available in pressure stages of 330, 365 and 420 bar. Based on 50 or 80 liter storage bottles, these storage systems can be expanded as desired.

How do I choose the right size storage system to limit on/off and charge cycles?

The information below provides the answer to this important question and helps you choose the right storage system for your needs.

A properly sized storage system (container) is one of the most important components of the overall system. Its purpose is to reduce pressure fluctuations during large and abrupt air outages and to reduce the frequency of compressor starts by means of adequate storage capacity.

In high-pressure compressors, it should be remembered that compressor end separators and storage vessels are only designed for a certain number of load cycles, i.e. the fewer switching cycles the compressor has, the longer the compressor life of these components.

In order to achieve optimal utilization of the plant and to reach the specified service life of the final separator based on the allowed load cycles, the compressor operation should be regulated in such a way that only a maximum of 4 switching cycles per hour are required.

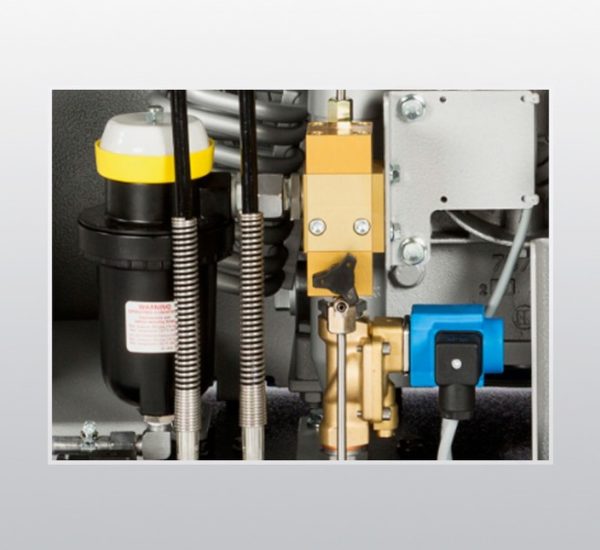

For your safety, BAUER industrial compressors are equipped as standard with a cycle counter to record the cycles actually performed.

The size of the storage system depends on:

- Compressor flow rate (l / min).

- Air consumption of the corresponding application.

- Pressure difference between on and off (hysteresis).

Simplified formula for the configuration of a high-pressure storage system based on 4 load cycles / hour:

| V (l) | = | Vk × 4

——— Δp |

| VK (L / MIN) | = | Desempenho do compressor em litros por minuto |

| V (L) | = | Volume de armazenamento em litros (volume de água) |

| Δ P (BAR) | = | Diferença de pressão liga-desliga (histerese) em bar |

We recommend a pressure switching difference Δp of max. 60 bar. Up to this difference, fixed high-pressure storage cylinders are generally approved for continuous operation.

In the case of larger differences, the containers are limited to a number of fillings.

Scope of Supply

Standard high-pressure storage module and auxiliary module.

| SISTEMA DE ARMAZENAMENTO | PRESSÃO NO TRABALHO | VOLUME GEOMÉTRICO | NÚMERO DE CONTÊINERES | VÁLVULA DE SEGURANÇA E MANÔMETRO | ||

| 330 BAR | 365 BAR | 420 BAR | LITROS | |||

| B50-S | – | x | x | cinquenta | 1 | x |

| B50-A | – | x | x | cinquenta | 1 | – |

| B80-S | x | – | – | 80 | 1 | x |

| B80-A | x | – | – | 80 | 1 | – |

| B100-S | – | x | x | 2 × 50 | 2 | x |

| B100-A | – | x | x | 2 × 50 | 2 | – |

| B160-S | x | – | – | 2 × 80 | 2 | x |

| B160-A | x | – | – | 2 × 80 | 2 | – |

High pressure horizontal storage system.

| SISTEMA DE ARMAZENAMENTO | NÚMERO DE GARRAFAS | VOLUME GEOMÉTRICO TOTAL | PRESSÃO NO TRABALHO | VERSÃO | ||

| LITROS | BAR | 1 BANCO | 2 BANCOS | 3 BANCOS | ||

| B800 | 10 | 800 | 330 | x | x | x |

| B960 | 12 | 960 | 330 | x | x | x |

| B1920 | 24 | 1920 | 330 | x | x | x |

| B2000 | 25 | 2000 | 330 | x | x | x |

| B2400 | 30 | 2.400 | 330 | x | x | x |

| B2800 | 35 | 2800 | 330 | x | x | x |

| B3360 | 42 | 3360 | 330 | x | x | x |

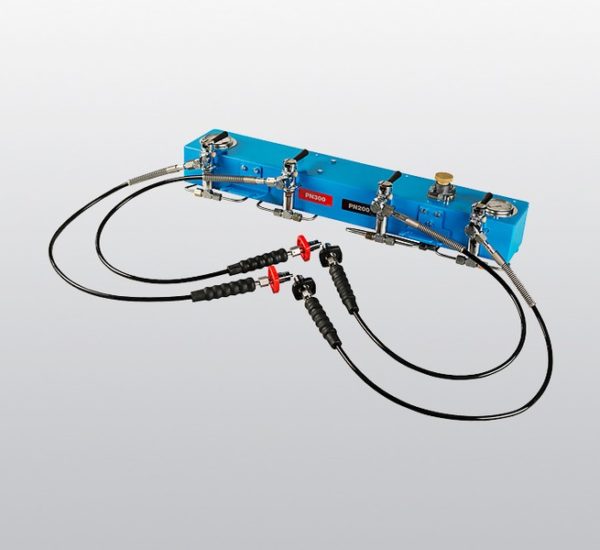

Filling and Safety

Fill your breathing air cylinders safely with breathing air compressed in your BAUER compressor: with an external BAUER filling panel or with the excellent safety filling system B-SAFE 300 that will protect against debris flying in if a bottle explodes.