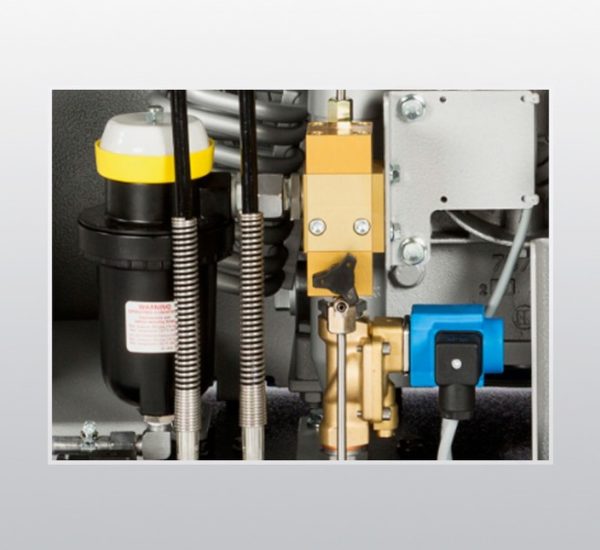

Compressed air passes from the compressor block to the final separator. Here, the condensate is mechanically separated, a mixture of small oil and water droplets, which is subsequently safely evacuated via the drain valve.

The previously purified air now flows through the P filter system, which absorbs the remaining water in vapor form, while removing hazardous substances from the breathing air.

In case of correct installation and maintenance of the systems according to the service manual and in case of use of the BAUER AERO-GUARD, provided the CO2 concentration in the aspirated air exceeds the predetermined standard values.

Whether you are a diver or a fireman who relies on pure breathing air according to DIN EN 12021 or you want to rely on perfectly treated compressed air for sports applications, for example when filling paintball cartridges – decades of experience of BAUER air treatment, intensive basic research and the most demanding material tests are aimed at extraordinary quality and highest safety.

Our goal in treating high-pressure compressed air and gas is to reduce fouling caused by moisture, CO, CO2, oil and particles.

The quality of the air generated by BAUER P filtration systems exceeds the requirements of the respiratory protection standard for compressed gases DIN EN 12021¹. Furthermore, the quality of the air generated with a BAUER filter system complies with the following international standards: STANAG 1079 mW, Britisch Standard 4001, US CGA Spec. G.7.1, Canada CSA Standard Z 180.1, Australian Army Standard 5017¹.

The prerequisites for this are the use of suitable BAUER filter cartridges as well as the correct location and regular maintenance of the compressor.

Other BAUER treatment systems and monitoring equipment provide additional safety in specific areas of application.

¹ In case of correct installation and maintenance according to the service manual and in case of use of BAUER AERO-GUARD, provided that the CO2 concentration in the exhaust air exceeds the predetermined standard values.