Technical principle:

The technical principle: During the condensate from the compression process, an emulsion of moisture from the air, lubricant and dirt particles from the ambient air are generated. For this reason, during and after operation of the compression plant, all intermediate separators mounted on the compressor and the final separator are continuously emptied (standard interval: 15 minutes, duration: 6 seconds). In this way, an aggressive oil-water mixture (condensate) does not remain in the compressor.

Control and automatic purging

Simple and intuitive operation of our portable compressors is realized via an integrated compressor control as standard. In the case of stationary installations, B-CONTROL controls and supervises all functions of the BAUER compressor installation.

An informative and user-friendly screen displays all information about the normal operating status of the installation. In case of detection of deviations, B-CONTROL automatically shuts down the compressor and shows the source of the error on the screen.

The advanced version of the B-CONTROL MICRO is the B-CONTROL II. This control offers additional convenient functions.

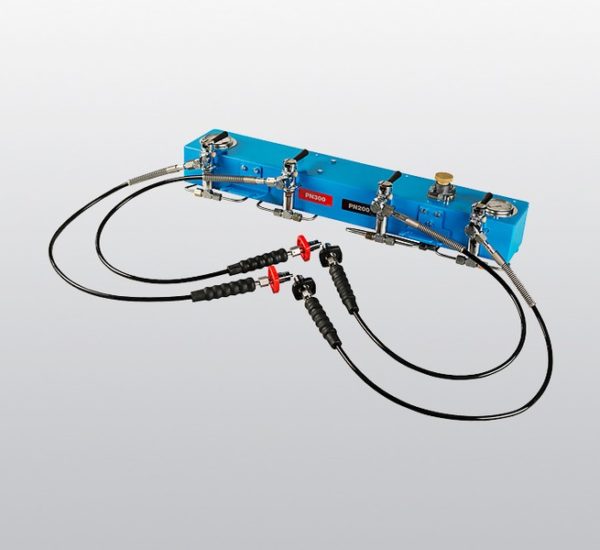

Fully automatic operation allows an automatic purge activated by an electronic control. The condensate generated can be collected in a collection vessel and disposed of in an environmentally compatible way.