Torque testers and analyzers, as well as simulators and joint transducers, provide fast, accurate results for the complete tool set. For users who do not have the in-house capability to calibrate their own tools, we offer calibration services for all brands of precision fastening tools.

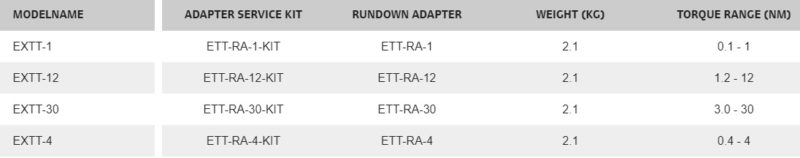

EXTT Series Torque Testers

The EXTT Series torque testers provide a quick and easy way to set up and calibrate low torque portable precision tightening tools, including electric and pneumatic screwdrivers, nut drivers, and push tools. As a battery-operated benchtop unit, the EXTT can be mounted in a calibration lab or toolbox, or placed on a mobile cart and transported to the jobsite. There are four models offering torque coverage from 0.1 to 30 Nm.

Features

- Integrated transducer with travel adapter

- Large, easy-to-read LCD display

- Easy-to-navigate icon-based menus

- Compatible with the full range of manual, electric and pneumatic precision tools

- Quick results download to PC or printer

- Monitors torque, angle, time, and pulse count

- Selectable torque units, filter frequencies, language and energy saving settings

- Automatic storage of time / date stamp readings

- Universal power

- Ability to generate complete statistics (Cp, Cpk, Pp, Ppk, CMK, CAM, range, mean, standard deviation)

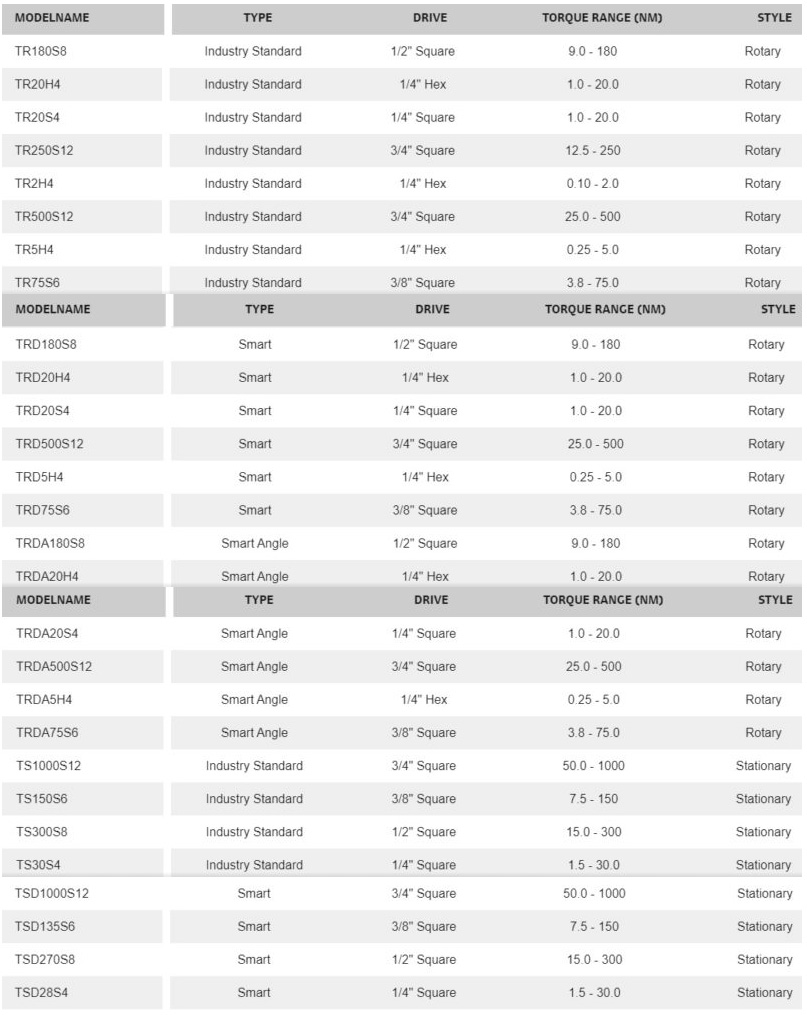

Stationary and rotary transducers

Available in stationary and rotary styles, the Expert transducers are designed to be used with the Expert EXTA Torque Analyzer or other analyzers to obtain accurate bidirectional torque and angle measurements on an actual threaded joint or in a joint simulator . Industry standard transducers can be used with third-party equipment that meets the industry standard. Smart transducers include a feature that allows auto-identification to an EXTA Expert torque analyzer for easy setup. Smart angle and torque transducers include an encoder for measuring angle.

Features

- 0.1 to 500 Nm (1 in-lb to 370 ft-lb)

- Use in a real joint or in a joint simulator

- Choose from industry standard or smart types

- Smart rotary transducers are available in torque or torque + angle versions only

Stationary transducers

- 1.5 to 1000 Nm (1.1 to 738 ft lbs)

- Use with articulation simulator

- Choose from industry standard or smart types

- Smart stationary transducers are available in a torque-only version

- JKST models combine an industry standard transducer and a joint simulator

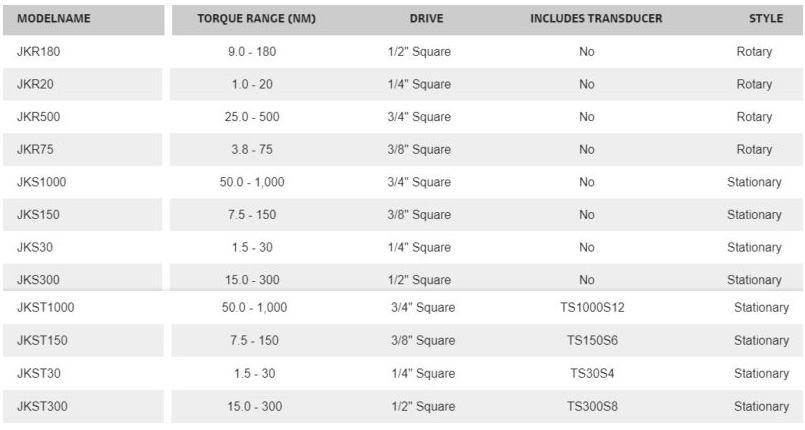

Joint Simulators

Specialized bond simulator kits are used to simulate different bonding conditions in the toolbox or in the lab, away from the actual bonding. The bond rate of the simulator can be easily modified to mimic different bond conditions, from hard to soft.

Features

- 1.0 to 500 Nm (1.1 to 370 ft-lbs)

- Compatible with industry standard and smart rotary transducers

Stationary Joint Simulator Sets (JKSxxx)

- 1.5 to 1000 Nm (1.1 to 738 ft lbs)

- Compatible with industry standard and intelligent stationary transducers

- JKST models include industry standard stationary transducers