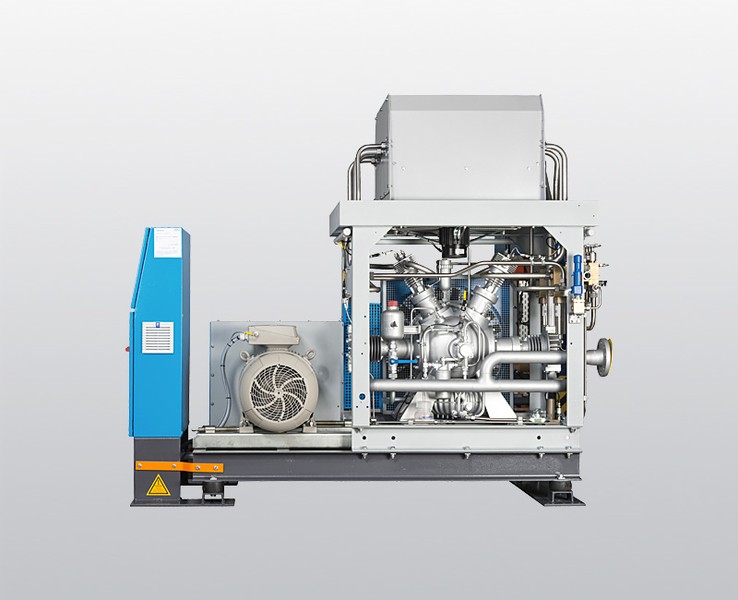

The air-cooled booster compressors of the GIB series from BAUER KOMPRESSOREN are characterized by their pressure-resistant housing up to 16 bar.

A powerful air-cooling system with large size chillers in combination with large area rifled cylinders provides perfect cooling of each compression stage.

As economical and long-life system solutions for difficult applications, these multi-stage booster compressors offer a wide range of possibilities: secondary air compressor for compressed air network, nitrogen compressor for inert gases from generators or storage system combinations, or gas compressor for compression of methane from pipelines or biogas directly from the treatment plant.

Adapted to individual wishes and industrial requirements, BAUER KOMPRESSOREN also manufactures tailor-made turnkey system solutions.